|

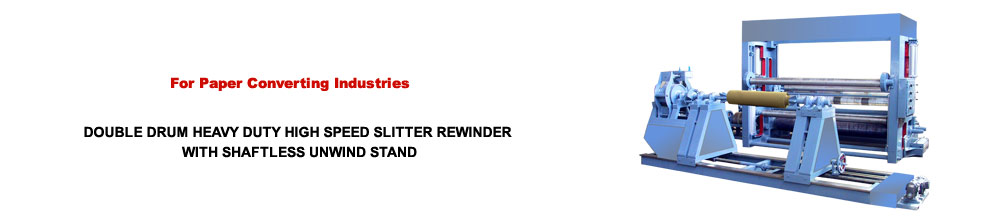

Heavy duty CI frame for the main body, with heavy tie-rod

construction, to ensure complete stability, vibration-free and noiseless

operation, even while operating at optimum speeds.

Unwind stations are available in shaft-less or

shaft-type/Tambour roll versions. The unwind stand can be shifted manually

or through motorized arrangement, for smooth sideways movement of heavy

reels.

Provision of longitudinal and lateral reel movements for

handling extra heavy jumbo reels.

Continuous water re-circulation system to instantly dissipate

the heat generated during braking operation by CI brake drum, or

pneumatically operated brake clamps.

High speed, silk smooth, high precision slitting station. "GNI"

incorporate scientifically designed slitting station with circular Top and

Bottom slitting knives. Users have an option to go in for mechanical or

pneumatic holders for holding top circular knives. User mills have further

option to opt for Bottom knives, to cut down on time involved in

bottom-knife spacer assembly work.

Channel box design steel strips construction camber bar for

thicker GSM papers Or camber roll provision for lower GSM grades of paper,

for easy separation of rewound reels .

Pneumatic system for reel ejection and unloading bucket with

slide arms for smooth unloading of finished reels after the required

diameter is built-up.

All rollers (guide rolls, dancing rolls etc) and drums are

dynamically balanced, to synchronize the web speeds.

Mechanically held cores with check nuts and clamping arrangement

on bearing housing at both ends Or an option of pneumatic holding

arrangement Or shaft-less rewinding bracket are available.

Pneumatically operated rider roll with variable geometry winding

system, exerting well designed pressure on rewound roll, to ensure

consistent roll quality for increased productivity and to ensure uniform

roll hardness through roll build-up, which is a pre-requisite for good and

marketable quality paper reels.

Motorized or mechanically driven Heavy wall thickness Twin drum

rolls of bigger diameter with grooves for surface winding operation to

built tightly rewound finish rolls.

| |

| Standard/Optional Features |

Twin Drum Heavy-Duty Surface Rewinding machine for paper mills.

Mechanical or pneumatic slitting station with multiple bottom

knives (Rewinder Blocks) or conventional bottom knife-spacer assembly.

Camber roll (for light / heavy GSM grades) for easy separation of

slit web.

Pneumatic Brake clamps on Brake drum or Disc type pneumatic

brakes with water cooling arrangement.

Provision for accommodating 1200mm to 1800mm dia. parent reels on

unwind and 1000 -1200mm dia. finished reels.

Pneumatic arrangement for Rider roll lifting/lowering and roll

ejector to smoothly push the finished roll to unload through Pneumatic

reel unloading device.

Dynamically balanced rollers for completely vibration free

operation and thick walled guide rolls.

And many more latest technical features.

|

+91 99 5356 1863

+91 99 5356 1863